Dye sublimation printing

Sublimation printing

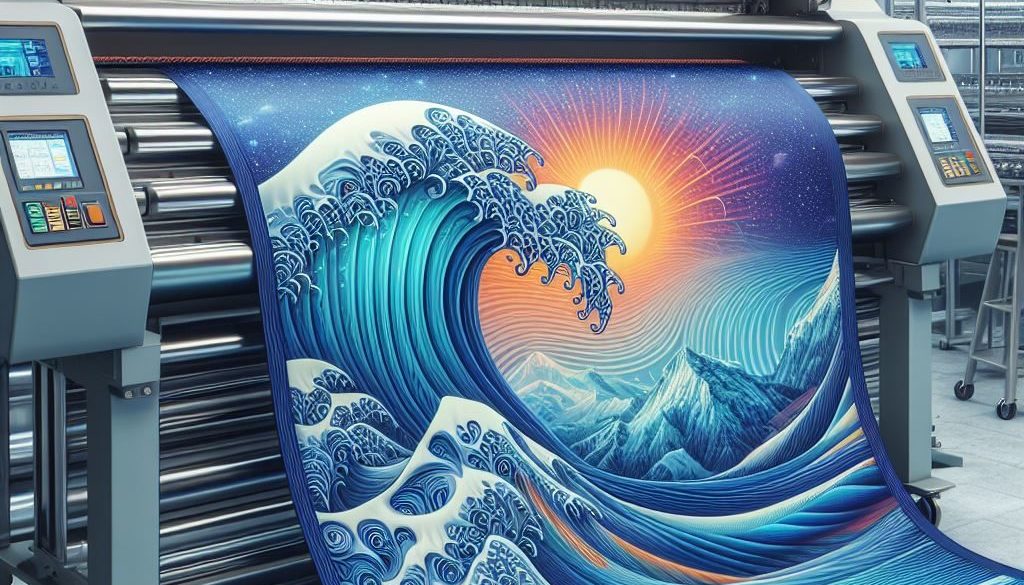

Technical Overview of Sublimation Printing on Polyester Fabrics

Sublimation printing on polyester fabrics is an advanced printing technique widely used to transfer images or graphics onto synthetic fabrics. This process harnesses ink sublimation, where ink transitions directly from a solid to a gas state without passing through a liquid state, enabling high-resolution and vibrant color printing on a wide range of polyester fabrics.

Basic Principles of Sublimation

Sublimation is a physical phenomenon where a solid substance transforms directly into a gaseous form without transitioning through the liquid state. In the case of sublimation printing, special ink containing colored pigments is heated and transformed into vapor, which penetrates the polyester fabric’s fibers and solidifies again, creating a permanent image.

Sublimation Printing Process

The sublimation printing process involves several key stages:

- Fabric pre-treatment: Polyester fabric must be adequately prepared to ensure optimal printing. This may involve removing surface impurities and applying chemical agents to enhance ink adhesion.

- Printing: The desired image is printed onto special paper using an inkjet printer with sublimation inks. It’s important to use inks specifically formulated for sublimation to ensure accurate color rendition and good stability over time.

- Transfer: The printed paper is placed onto the polyester fabric and subjected to heat and pressure using a calender or heat press. Heat activates ink sublimation, transforming it into vapor that penetrates the fabric’s fibers. Once cooled, the ink solidifies again, creating a permanent image on the fabric.

- Finishing: After transfer, the fabric may undergo additional finishing processes, such as calendaring to improve gloss and softness.

- High print quality: Sublimation enables high-resolution prints with sharp details and vibrant colors.

- Wash resistance: Sublimated prints penetrate the fabric’s fibers, ensuring superior wash and wear resistance compared to surface printing techniques.

- Wide color gamut: Sublimation allows for a wide range of vivid colors and precise shades.

- No design constraints: Sublimation printing allows for printing complex and detailed designs across the entire fabric surface, without limitations on the number of colors or design complexity.

- Sportswear: Jerseys, shorts, and other sportswear can be customized with logos, graphics, and unique designs through sublimation printing.

- Home furnishings: Fabrics for curtains, cushions, tablecloths, and other home furnishings can be decorated with customized prints using sublimation.

- Merchandising and promotion: Gadgets, flags, banners, and other promotional items can be customized with logos and advertising messages through sublimation printing.

Sublimation printing on polyester fabrics is a versatile and advanced technique that offers high-quality, durable, and versatile design options. Thanks to its ability to produce vibrant and long-lasting prints on a wide range of fabrics and applications, sublimation has become a popular choice for customizing clothing, furnishings, and promotional items. With proper fabric preparation and the use of high-quality inks, extraordinary results can be achieved to meet even the most demanding design needs.